Introduction

Recent driving simulators have reached a level where they can run large-scale physics-based simulations, reproducing vehicle behavior and acoustic phenomena with high fidelity. In modern automotive development, the concept of zero prototype development—building virtual prototypes in digital environments instead of producing physical test vehicles—has become increasingly important for reducing both development time and cost.

In acoustic development, the trend has shifted from broad, integrated noise evaluations to approaches that can isolate the influence of specific components. Unlike engine noise, which is broadband and high in sound pressure, tire noise is narrower in frequency range at each mechanisms and far more complex in its generation mechanisms, requiring precise and detailed simulation methods.

Three Levels of Simulation on Driving Simulators

Today’s cutting-edge driving simulators approach tire noise simulation through three levels of sophistication:

- Level 1: Using in-cabin measured sounds with signal processing

Directly applying processed in-cabin measurements from real vehicles. Fast and straightforward, but heavily dependent on experimental data and hard to apply for tire development. - Level 2: Using transfer functions from components

Applying acoustic transfer functions from specific parts of the vehicle, separating sound sources from transfer properties. This makes it easier to analyze causes and evaluate design changes. - Level 3: Using CAE model data

Utilizing structural and acoustic Computer-Aided Engineering (CAE) models directly. This offers high-precision, physics-based analysis but comes with higher computational and modeling costs.

By organizing simulation approaches into these three levels, engineers can select the most suitable method depending on project goals, cost, and accuracy requirements.

Types of Tire Noise and Evaluation Guidelines on Driving Simulators

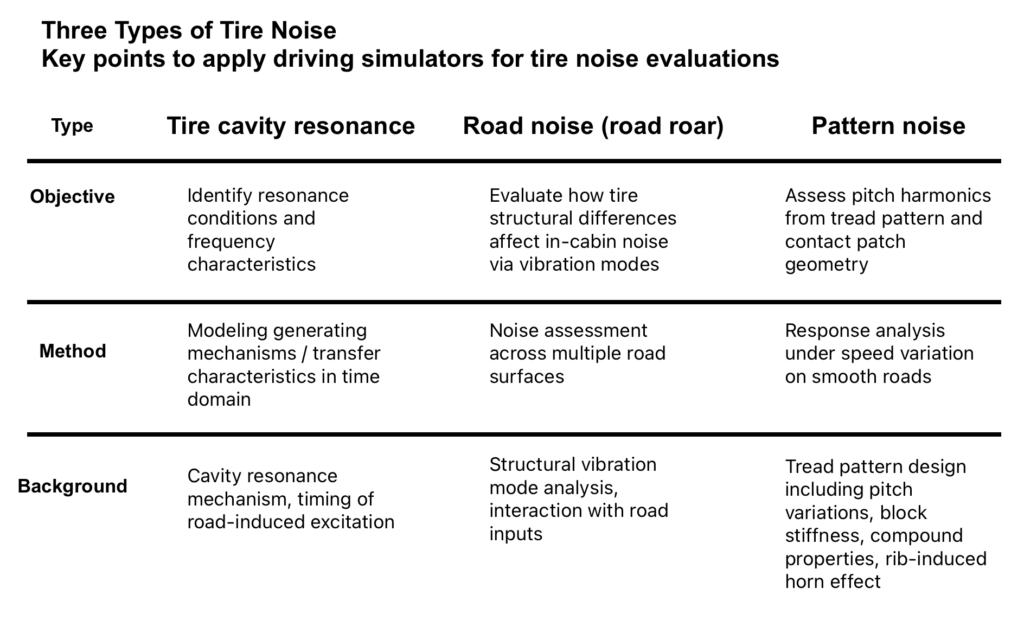

Tire noise itself can be broken down into three categories, based on the underlying generation mechanisms:

1. Tire Cavity Resonance

- Objective: Identify resonance conditions and frequency characteristics

- Method: Modeling generating mechanisms /transfer characteristics in the time domain

- Background: Cavity resonance mechanisms and timing of road-induced excitation

2. Road Noise

- Objective: Evaluate how structural differences in tires affect in-cabin noise through primary and secondary resonance modes

- Method: Assess noise characteristics across multiple road surface conditions

- Background: Structural resonance analysis and interaction with road input mechanisms

3. Pattern Noise

- Objective: Assess pitch harmonics caused by tread pattern design and contact patch geometry

- Method: Response analysis under speed variation on smooth road surfaces

- Background: Block stiffness, compound properties, and rib-induced horn effects

Outlook

By combining the three simulation levels with the three noise categories, engineers can systematically link objectives, methods, and engineering backgrounds. This enables:

- Optimizing internal structures to suppress cavity resonance, approached by psychoacoustic insights into tonal perception

- Deriving structural design guidelines for reducing road noise

- Selecting tread patterns and compounds to control pattern noise

Ultimately, tire noise simulation on driving simulators is more than just an evaluation tool—it is becoming a strategic asset that supports both enhanced in-cabin comfort and greater development efficiency in the automotive industry.

No responses yet